The Part of Industrial Metal Detectors in Producing

As production processes turn into significantly complex, the job of industrial metal detectors hasn't been extra significant. You'll want to make certain steel detection efficiency to maintain products integrity and safety.

By integrating State-of-the-art metallic detection programs, you may swiftly detect and eliminate contaminants before they get to The buyer, safeguarding your brand name's name. This proactive approach not merely enhances excellent Command and also improves producing performance.

If you put money into trusted steel detectors, you streamline functions, reduce pricey recollects, and limit downtime. What's more, reliable detection processes make it easier to adjust to market laws, even more solidifying your operational standards.

Within this competitive landscape, leveraging powerful steel detection is essential for sustaining quality and optimizing productivity, allowing you to stay in advance in the curve.

Varieties of Steel Detectors Utilized in A variety of Industries

Comprehension the precise types of metal detectors employed throughout several industries is significant for optimizing basic safety and top quality Manage.

Handheld detectors are sometimes used for rapid inspections in places where by mobility is critical. In contrast, conveyor programs are integral to ongoing manufacturing lines, detecting contaminants devoid of interrupting workflow.

For pipeline inspection, specialized detectors make sure metal fragments are identified in advance of they compromise integrity.

Automotive purposes use Sophisticated steel detection technologies to take care of stringent excellent requirements, though the textile marketplace relies on these detectors to circumvent metallic contamination in fabrics.

Every sort serves a distinct reason, personalized to the specific wants with the industry, enhancing product or service safety and operational performance.

How Steel Detectors Work: A Specialized Overview

When several may perhaps visualize metallic detectors as straightforward devices, their Procedure entails subtle technologies that assures precision and dependability.

Within the Main, metallic detectors crank out a magnetic field that interacts with steel objects, triggering them to produce secondary signals. These alerts are then captured and analyzed by means of Sophisticated sign processing approaches.

You may make sensitivity changes to boost detection capabilities, letting the system to recognize even the smallest contaminants. The procedure filters out track record noise, guaranteeing that only pertinent alerts cause alerts.

The Importance of Metal Detection in Food stuff Protection

Steel detection plays a critical function in making certain food items security, because the presence of even the tiniest steel contaminants can pose serious health hazards to individuals.

Food stuff contamination can take place at various stages of output, from Uncooked materials to packaging. Making use of advanced detection technologies, you could identify and remove these contaminants prior to they reach the marketplace.

These systems, such as electromagnetic and inductive strategies, enable sustain higher specifications of high quality Management. By implementing sturdy steel detection units, you're not only defending buyers but in addition safeguarding your brand's name.

Regular upkeep and calibration of those techniques be certain They are performing optimally, allowing you to definitely adjust to foodstuff protection laws and cut down opportunity liabilities.

Prioritizing steel detection is essential for any meals manufacturing Procedure.

Making sure Pharmaceutical Integrity With Steel Detection

While in the pharmaceutical market, maintaining product or service integrity is equally as essential as in food items safety. Pharmaceutical contamination can result in severe wellness dangers, merchandise remembers, and lack of customer belief.

That's why successful detection techniques are important. You need to think about utilizing advanced metallic detection techniques that may discover even the smallest metallic fragments throughout generation. These techniques benefit from electromagnetic fields and sophisticated algorithms to ensure products purity.

Frequently calibrating and validating these detectors can help preserve precision and compliance. By integrating metal detection into your good quality Management processes, you not just safeguard your items but also boost your brand name's status.

Regulatory Requirements and Compliance for Steel Detection

As regulatory bodies ever more emphasize the significance of metal detection in producing procedures, businesses must continue to be knowledgeable in regards to the relevant standards and compliance requirements.

Knowing regulatory compliance is very important for making certain that your products and solutions meet up with marketplace requirements. Companies like the FDA and ISO define distinct suggestions for steel detection, which enable preserve product safety and top quality.

You will need to apply steel detection devices that not merely comply with these specifications but additionally undergo standard tests and validation processes. By adhering to founded protocols, you minimize the risk of contamination and guard your manufacturer's integrity.

Keeping proactive about regulatory updates makes certain that your functions align with latest marketplace requirements, in the end leading to far better client trust and reduced liability.

Great things about Implementing Steel Detectors in Manufacturing Lines

Employing steel detectors in manufacturing lines not simply improves item high quality but additionally safeguards your model's status. By detecting contaminants early during the manufacturing process, you considerably reduce the risk of pricey recollects or legal challenges.

These detectors help make certain compliance with business restrictions, boosting client believe in and loyalty. Also, integrating steel detection engineering contributes to considerable Price tag personal savings by minimizing waste and downtime a result of products contamination.

You'll also experience improved operational performance, as metallic detectors streamline high quality control procedures. In the end, purchasing metal detectors don't just shields your solutions but in addition fortifies your manufacturer from possible challenges, permitting you to definitely concentrate on advancement whilst preserving significant security expectations.

Common Programs of Steel Detectors Across Industries

Metallic detectors Participate in an important function throughout several industries, making sure security and excellent in diverse applications.

During the automotive elements sector, they detect contaminants that may compromise car or truck effectiveness.

In electronics manufacturing, they safeguard delicate elements from metal particles.

The textile field Added benefits by pinpointing foreign objects that may destruction material.

Construction products endure scrutiny to stop metallic impurities from affecting structural integrity.

Recycling operations employ metallic detectors to improve materials Restoration.

For the duration of packaging processes, they help keep product or service purity.

In chemical creation, they make certain that dangerous metals Really don't compromise safety.

The woodworking sector depends on them to identify metallic in timber.

Ultimately, aerospace components should be free of contaminants, creating metal detectors crucial in mining programs, much too.

Problems in Metal Detection And exactly how to beat Them

Though metal detectors provide several industries properly, numerous problems can hinder their overall performance and dependability. Just one key issue is detection accuracy, which may be compromised by numerous contamination resources, for instance merchandise composition, environmental circumstances, and machine interference.

By way of example, higher moisture articles or metal packaging may possibly mask more compact contaminants, bringing about Bogus negatives. To overcome these issues, you should perform frequent sensitivity tests and be certain good positioning of your detector throughout the manufacturing line.

On top of that, schooling staff members on figuring out potential contamination resources will greatly enhance detection abilities. By addressing these things, you'll be able to considerably Enhance the success of steel detection devices, in the end making sure product or service basic safety and maintaining high quality Handle across your operations.

Routine maintenance and Calibration of Steel Detection Machines

To make certain optimum overall performance of metallic detection tools, regular upkeep and calibration are vital. You ought to establish precise maintenance schedules that come with regime inspections, cleansing, and section replacements. This proactive method minimizes breakdowns and extends the lifespan of your machines.

Through upkeep, spend close consideration to components like coils and sensors, as these are critical for exact detection.

Calibration techniques has to be performed periodically to take care of detection precision. This entails employing calibrated examination pieces that mimic likely contaminants. By documenting these methods, you make sure compliance with marketplace benchmarks and boost dependability.

Also, schooling your staff on these procedures permits consistency and efficiency, contributing to Over-all item safety and excellent Command in your functions.

Foreseeable future Traits in Industrial Metallic Detection Technology

With developments in engineering, the landscape of high performance magnet separator industrial metallic detection is evolving swiftly. You are going to recognize AI progress maximizing detection precision, allowing for for smarter detection strategies that decrease Bogus positives.

The integration of advanced sensor know-how is important, enabling devices to recognize lesser contaminants with precision. Automation integration streamlines processes, reducing manual oversight and increasing performance.

On top of that, info analytics plays a vital part in interpreting detection effects, providing actionable insights for top quality Regulate. Compact designs make these units less complicated to put in and sustain, while intuitive user interfaces increase usability.

Circumstance Research: Results Stories in Merchandise Security Via Metal Detection

As companies significantly prioritize merchandise safety, numerous scenario scientific studies highlight the efficiency of industrial metal detection in avoiding contamination and protecting people.

One results Tale consists of a number one snack company that integrated advanced metal detectors into their output line. This innovation resulted in a 30% reduction in product remembers as a result of contaminants, improving manufacturer reputation and shopper have confidence in.

One more case examine contains a beverage company that expert an important decrease in overseas object issues just after deploying state-of-the-artwork detection systems.

These merchandise innovations not just ensured compliance with basic safety laws but also enhanced operational efficiency.

Summary

In summary, industrial metal detectors are important for keeping products protection and high quality control across industries. By catching contaminants early, you're not just safeguarding shopper overall health; you might be also defending your manufacturer's reputation. As know-how continues to evolve, being forward in the curve is crucial. Keep in mind, an ounce of prevention is really worth a pound of treatment. By purchasing trusted metal detection, you are going to make certain compliance, reduce recalls, and in the end elevate your merchandise criteria.

Marla Sokoloff Then & Now!

Marla Sokoloff Then & Now! Kelly Le Brock Then & Now!

Kelly Le Brock Then & Now! Mason Reese Then & Now!

Mason Reese Then & Now! Katey Sagal Then & Now!

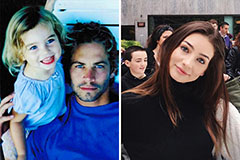

Katey Sagal Then & Now! Meadow Walker Then & Now!

Meadow Walker Then & Now!